Yesterday morning I woke up to a house without electricity - that meant I woke up in a puddle of sweat because the fan was no longer turned on. It turned out that my housemate, while making coffee, had tripped the mains of the house. The kettle had caused the trip. It was no longer safe to use the kettle and so I had to buy a new kettle.

Lately, I had coincidentally been considering buying a new kettle to replace the old one, which I have used since 2007. I was also kinda tired of sticking a thermometer in the water to figure out the temperature of the water before I brew my coffee or tea. However, I never actually had a good reason to do so. The kettle we had was absolutely serviceable, and there wasn’t a good reason to change it. Now I do.

And so, I took a break from writing my book on Javascript interview questions (alternate title: Underhanded Javascript) and hopped online to find the best variable temperature control kettles I can find. Being the coffee and tea snob that I am, I perused a number of forums, looking for the best recommendations for such a kettle. I narrowed my choices down to the Breville BKE820XL($149), the Cuisinart CPK-17

(115 dollars), or the Sunbeam KE9450 (100 dollars). The main reason why I shortlisted them was because they had temperature control. There was also another brand that was mentioned - Shark, or Belle, or Da Vinci - basically Chinese knockoffs of the Cuisinart.

The one thing I noticed about these is that they all cost more than 90 dollars, which is way more than what I’m willing to pay for a kettle. My old kettle had cost me something like 10 dollars from K-Mart. I wasn’t very willing to part with so much money for a kettle. So I decided to look for a cheaper version - I was willing to forgo the temperature control - afterall, I had been using a manual thermometer for years and it didn’t affect my making tea or coffee.

My housemate had also mentioned earlier that she would not prefer a plastic kettle and would prefer something metal. And so I went to look for normal electrical kettles. To my frustration - all the basic kettles cost roughly the same price: $39. The branded ones cost slightly more, and the non-branded ones cost slightly less. Why in the world would it cost so much? A kettle is not something difficult to build. The most difficult part is the grounding of it - which metal kettles are in sore need off, lest they give you an electric shock. But it’s really not that difficult to build a kettle, nor does it cost that much.

How to Build a Kettle With Temperature Control

I'm a big fan of conceptual thinking. I've once complained about some of my acquaintences' inability to even conceptually build something, what more actually building something. In Programming PearlsSo I began to conceptually build a kettle with temperature controls. I chose a top-down approach to building this in my mind. First, I built a mental model of what is needed in a basic kettle: a heating element, a receptacle to store liquid while it boils, some sort of automatic off switch - probably heat powered - to turn the switch off once it hits boiling point. Then I think about what extra stuff are needed to build the same kettle, except with temperature control. Temperature control indicates that a) a reading of the temperature of the water is required; b) a switch that could understand the reading of the water temperature.

This implied only one thing: a PID, and a relay of some sort. I know what PIDs cost - I own a couple of PID controllers and have built one from scratch. Because of the cost, that also meant that the kettle that I currently have (and that is broken), cannot possibly be digitally controlled - it’d cost too much.

Dismantling the kettle

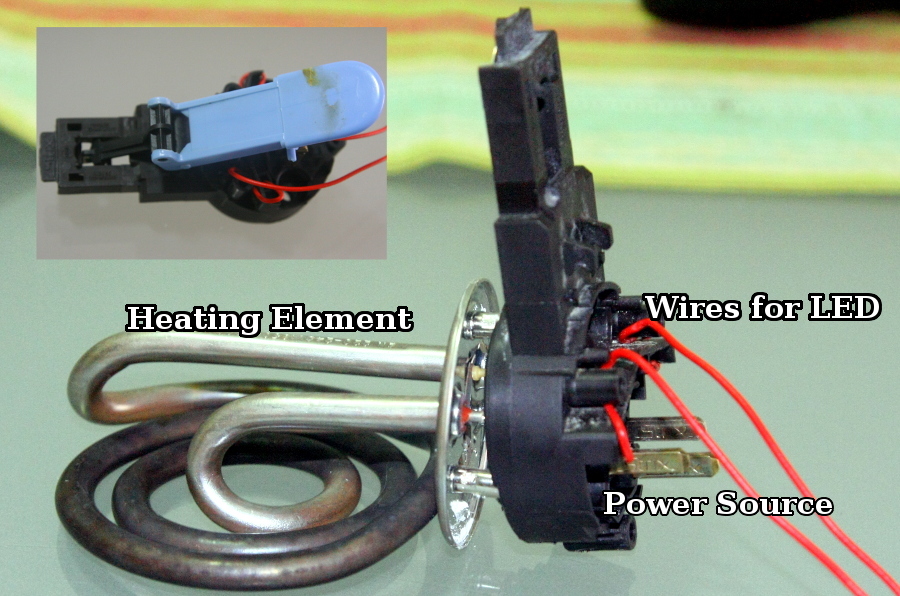

So out of curiosity, I began to dismantle my kettle. A kettle is an extremely simple electrical appliance, really. A heating coil heats up water. When it is hot enough, it stops. And I was right - it was ridiculously simple. It simply consisted of a switch, a power source and a heating element:

I had removed the switch to remove the heating element from the jug. The image above shows a reconstruction of how the power supply connects to the heating element. Inset is the power supply connected to the switch. The red wires are to a LED which tells you that the heating element is turned on.

However, I was still puzzled by how the kettle would automatically turn off when the water boiled. And so I looked carefully at the details of everything in the kettle. Suddenly it hit me. I was looking at it all along, and it was staring back at me:

OK, paredolia asides, the metal strip in the middle actually plays a very important part in the analog automatic control. I had actually seen one of those before when I was very young. It’s actually a bimetallic strip that curls outwards when heated. It’s basically 2 pieces of metal that is pressed into one strip. Because the different metals have different expansion rates when heated, heating a bimetallic strip would cause it to bend one way.

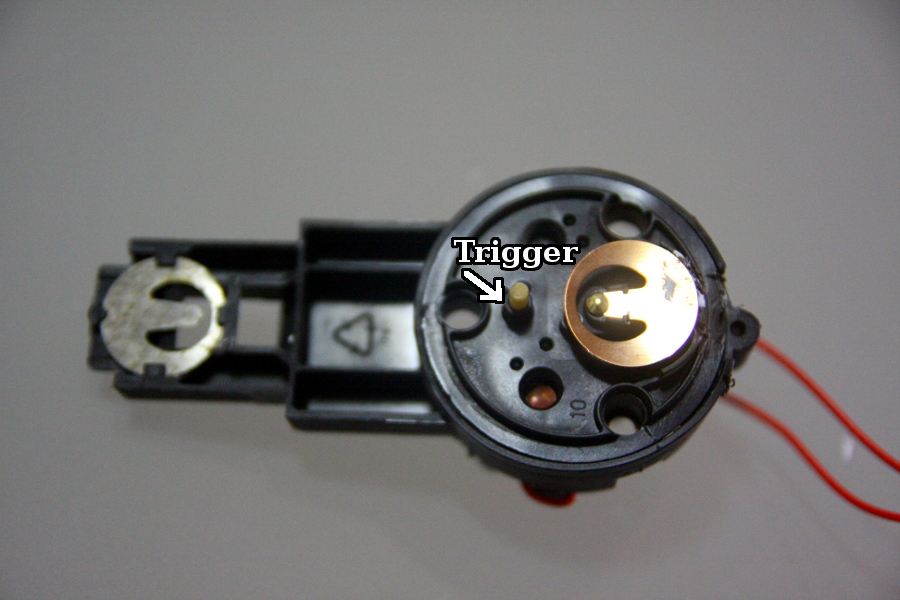

To prove that, I took a blowtorch to it and it curled outwards exactly as I thought it would. When it cooled down, it became a flat strip again. The metal strip curved outwards. It must trigger something. Looking at the back of the power source, I found what it triggered - a spring loaded switch. Here’s how the back of the power supply looks like:

The way the kettle is constructed, the heating element and the power source are pressed together when the blue switch is pressed down to turn on the kettle. The switch is basically a see-saw. When it’s pressed down, the lever will latch on at the top (the silver coloured piece in the picture above), pressing the power source towards the heating element. The copper piece in the picture above comes into contact with the metal base plate of the heating element, and the circuit is complete. The heating element heats up.

When the bimetallic strip gets heated up, it curls outwards, pressing on the trigger. The trigger, when pressed, pushes the lever outwards, causing the latch to unlatch. Once the latch is undone, the power source is no longer pressing onto the base plate of the heating element. The circuit is broken, and the water stops heating.

There is a certain elegance to these analogue systems that one must be able to appreciate. Using a bimetallic strip to trigger a mechanical trigger is simply quite a brilliantly elegant way of solving a problem. There is no reason to build an expensive kettle with digital controls if perfectly cheap and simple analogue solutions like these exist.

How Much Does A Basic Kettle Cost

Once one knows how something works, the magic is lost. Very quickly I began tabulating how much it would cost to build and market a kettle. My answer came to a little over 7 dollars. Even with the fanciest metal designs, I estimate it'd cost no more than $12 to make and market a basic kettle with no bells and whistles. Even with the most generous of all estimates - which is to say extremely expensive industrial designers were hired to craft the shape of the bottle (let's assume we're talking about something like the Bugatti Vera.), and that the manufacturer uses the most expensive possible manufacturing tools, the price over a mass amount of units (say 100,000 units) would not cost more than 16 dollars.So why did the rest of the basic kettles cost 39 dollars? Given the almost-same price from all the brands, they all have to function on the same principle essentially. They’d also have to have pretty much the same fixed and variable costs. If we assume we see the market in action, then that would mean I was wrong. It didn’t cost 16 dollars to manufacture and market those kettles. The problem is, there exist on the market, homebrand kettles that cost $10 or so. If both homebrand and branded kettles use a similar principle, then it would be cause to wonder why the basic kettles of the bigger brands all cost 39 dollars.

Unless of course, those 39-dollar kettles use a digital solution to stop the water from boiling. But that is just rather silly, given that an analogue solution works better. I do not see how a digital solution is actually a superior solution. It’s rather like saying replacing your car’s control panel with a touch screen is a better idea - oh wait. Tesla actually thought this was a good idea. It isn’t.

Given that a digital control solution is not going to be much superior (and in fact, like the Tesla example, could actually be inferior) - water has ONE boiling temperature - 100 Celcius, why would a basic kettle cost $39 and up? Yes, I mean, people could be paying for the design (because a red kettle is so going to boil water faster than a white kettle), but really, there is no basis in reality to pay for such an expensive kettle. Especially so if the basic kettle is digitally driven. It’s just a waste of time and energy of the designers, trying to cramp so much electronics into a small space.

No, rather, basic kettles from bigger brands cost $39 as a form of price differentiation. Consumers who can afford to pay more, or do not know better, would pay more for the same basic product. Anything extra is mostly cosmetic and has no say on the functionality (or if it does, like for example, if the shape or material of a kettle would help it retain heat better, it doesn’t add much marginal utility).

How to Build a Kettle With Temperature Control - pt2

Which brings me to why I actually want a kettle with temperature control. Unlike a basic kettle, I understand why a more advanced kettle with variable temperatures would cost so much more. As previously mentioned, having temperature control means requiring something to read the temperature of the water - a temperature probe (I own a couple of PT100 probes myself), and a PID controller. Those things are not cheap, even if one buys them in bulk. A basic PID would set one back about $30 (and that was the best bulk price I could get). With PID controllers also come costs of hiring electronic designers, and micro-controller programmers. Also, a relay is required to turn on and off the kettle, instead of mechanical solutions like the one above. Furthermore, these electronics have to be heatproofed. A kettle is a very hot thing, and the microcontrollers in the kettle must not fail under heated circumstances.All these little things add up. But it’s actually useful. Instead of hiring electronic designers, programmers, and using electronics for basic functionality, the main use is for precision boiling. And that’s a good use. This is one of the main reasons why I am looking at variable temperature kettles (okay, I admit, it’d make my life a lot easier too, if I didn’t have to stand and take the temperature of the water every time I make my coffee or tea).

The reason is I don’t feel ripped off paying for a variable temperature kettle. Knowing how a basic analogue kettle works and especially knowing how much it would cost to build one, I would feel terrible if I had to spend $40 on a kettle that works exactly the same way in principle. And yes, before you ask, the ones I saw, they DO work on the same exact principles. How do I know this? The switch in those kettles are mechanical. A digital kettle wouldn’t have a mechanical switch (you can design one that has, but I don’t see the point).

Why Does A Good Kettle Cost $90+?

Here's a rough bill of materials/services and estimates I came out with, assuming a unit cost over 100,000 units in a production run:| Description | Estimated Cost |

|---|---|

| Manufacture of kettle body (metal, because plastic is so pedestrian) | $5 |

| Industrial design of kettle body (assuming 3 high calibre ($100k p/a) industrial designer) | $7 |

| PID Controller + other electronics | $10 |

| Heating element | $3 |

| Electronics engineer (assuming 3 electronics engineer and 2 test technicians) | $7 |

| Various manufacturing fixed cost (safety tests, product tests, etc) | $5 |

| Marketing, stocking, etc fees | $5 |

It comes close to $45. And these are on quite generous assumptions. I have no doubt that given the scale of these big branded companies, they would have more economies of scale and scope to reduce these costs even further. Of couse, this being a mental estimate, it could go very wrong. It could be the companies don’t manufacture 100,000 units per run. That would change things quite a bit.

This means a markup of double. But the main reason why I would rather go for a 90-dollar kettle instead of a 39-dollar kettle is because the 90-dollar kettle does a lot more. There is quite a bit more function per dollar than the $39 one.

But ...

Of course, then there's the Hamilton Beach programmable kettleAs for which kettle I bought, the house is currently kettle-less while I figure out which one to buy. I’m leaning heavily on the Cuisinart CPK-17. I am also quite partial to just buying a water warmer like the Zojirushi

, mainly because my mum uses one and I grew up with one, but who knows, I might just go buy another $10 kettle.

TR;DR: I seem to have given a lot of thought to buying a kettle (this article is 2250 words long). I come to the conclusion that expensive basic kettles are the same as cheap basic kettles, except for price differentiation. The increase in marginal utility from purchasing a expensive kettle is not big enough compared to buying a baseline cheap kettle to warrant it. It’d be better to buy a temperature control kettle, as then the increase in marginal utility would be enough to warrant puchasing it. What do you think?